As a specialized supplier of complementary solutions for electrical safety equipment, LAIWO offers technical solutions for circuit safety that work in harsh environments.

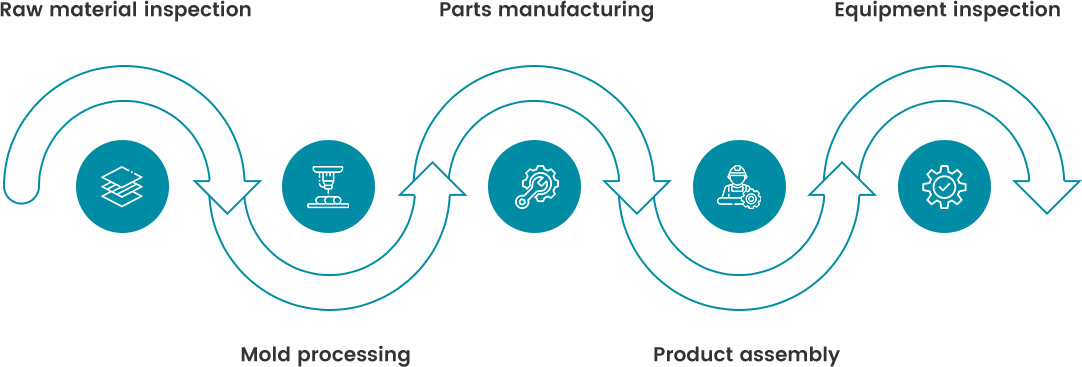

We understand that a comprehensive quality policy is an important condition for long-term business partnerships. Therefore, strict quality management is practiced in our production and processes.

We have strict standards for the procurement of raw materials. Distribution boxes are made of high quality iron shells and copper terminals to ensure the appearance and conductivity of the double good;

fuse shells are made of insulated flame retardant materials, corrosion resistance, long service life; circuit breakers, disconnect switches and other shells PA66 material, containing T2 copper, safe and reliable.

The degree of automation of our processing center is high, and in the production process of molds, we can realize the spray automation and full-automatic injection molding.

The automated processing makes the dimensional accuracy of product spare parts more accurate and the defective rate greatly reduced.

INQUIRY NOW